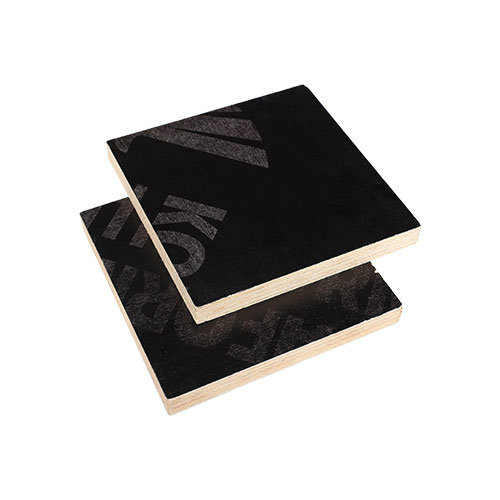

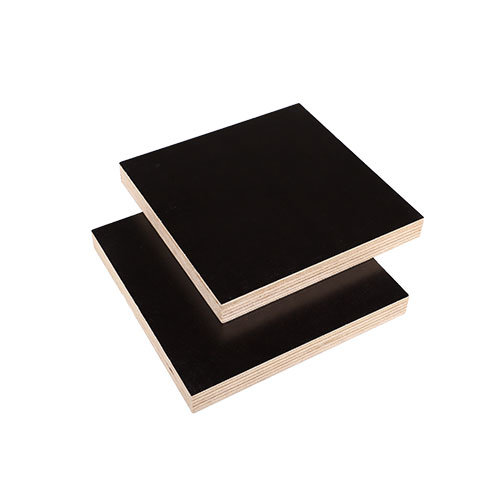

What is Film-Faced Plywood?

Film-faced plywood is an exterior plywood used in building and construction projects. It has a higher resistance to moisture, abrasion, chemical degradation and fungus compared to ordinary plywood products.On both sides of the plywood there is a film coating made of phenol or melamine.How is Plywood Made?

Plywood is a wooden material that is protected from external factors such as water and moisture, by stacking thin layers of wood material on top of each other for a flat floor, placing them crosswise at right angles, and sticking them with the help of an adhesive such as glue, and placing a protective layer on top of it.What is Birch Plywood?

Birch plywood is a plywood panel made entirely of birch wood, covered with a film on both surfaces by sticking it with a glue such as water-resistant WBP (Water Boiled Proof) and pressing it under high heat.The panels are not made from a single piece of solid wood, but from multiple layers or layers of veneer.

The number of layers depends on the thickness of the panel, its intended application, as well as the manufacturer's specifications and processes.

In addition to film-faced plywood products, you can also access filmless plywood, ecological marine plywood products with Baba Yapı.

Birch Plywood Usage Areas in Construction

It is used in various applications such as joinery works, furniture production, structural/industrial applications, model making, plywood underlay, mold work, home improvement and small construction projects.Sanded panels are available for cabinet, furniture and joinery applications and rough panels are available for industrial/structural needs. Panels are available in varying surface grades, glue lines, core structures, various sizes and thicknesses.

Durability of Plywood

Plywood is used in many areas, from construction to furniture and various building materials.Water-resistant WBP is resistant to water, moisture and chemical materials thanks to its adhesive bonding and pressing.

Although it is made of a lightweight material compared to other wood products, it is more durable.

There is almost no possibility of cracking and splitting during nailing or transportation.

Since it is glued diagonally, there are also no pulling and swelling problems.

What are the Usage Areas of Film-Faced Plywood?

Film-faced plywood has a light weight. It is also resistant to abrasion and water. It is simply combined with different ingredients. The issue of its cleaning and cutting is also quite easy. Due to its durability and easy-to-process surface, it can be used in many areas. These are;- Construction and buildings

- Warehouses, railway wagons,

- Such as the floors and sidewalls of trucks in open environments,

- It is also used in the manufacture of furniture such as chairs, tables, sofas and beds.

The fact that the film-faced plywood is covered with quality films ensures that it has strong rigidity and damage resistance. Since the surface of film-faced plywood is very hygienic, it can be used comfortably in areas such as agricultural structures and storage of food products. It is also resistant to strong detergents, which is important for cleaning. It can be used in low temperature, humidity, detergent cleaning conditions.

It also provides protection against termites. It is also used in the construction of furniture besides chairs, tables, couches, beds, etc.

Waterproof Film-Faced Plywood

Film-faced plywood is quite durable against moisture, water and various chemical materials that threaten living quarters and make it difficult to live. Waterproof acrylic becomes more resistant to water and abrasion with the use of latex paints or oil-based paints.How to Cut Film-Faced Plywood?

Film-faced plywood materials, which are widely used in different fields, have a layered structure.As the number of layers increases, its durability also increases. It is cut into single layers, then these layers are combined and a special film is coated on both sides. The cutting of this material can be carried out in the carpenter's workshop or at home. It is necessary to have some materials that can be used for this.

- It is important to choose the right saw blade to get a chip-free edge. The size and adjustment of the tooth of the saw blade used is the important point here. The smaller the size of the resulting chips, the smaller the size of the saw tooth. It is one of the most important elements in choosing a circular saw. Alignment and adjustment of the cut can be done with the help of a ruler.

- Decoupage knives are more diverse. It is used for a clean cut without chips. Usually the series of knives from the BOSCH brand CleanWood is used. They have small dimensions and a certain orientation of the teeth. They have the form of an isosceles triangle and cut in both directions.

- There are some cutting techniques used by carpenters.With the zero gap technique, the crust breaking effect on the upper layer of the material is eliminated.

With this kind of tapes, it is possible to make the highest quality cutting.

How to Paint Film-Faced Plywood?

It is important to make a choice of paint for the painting process, which will increase the durability of the film-faced plywood material. A paint should be selected in accordance with the work to be done.In furniture and general usage areas, durable acrylic latex paints and oil-based paints should be selected.

The use of a spray gun for large areas will save time. The painting process is carried out in several steps:

- The important aspect in the painting process is the choice of brush. The brush to be used must be compatible with the paint and primer.

- For the painting process, first of all, the area that is undesirable to be painted should be covered with a tape beforehand.

- If there are surfaces that need to be sanded, sandpaper should be applied. But before this procedure, if there are gaps, they must be filled.

- The use of a paint brush in the painting process can provide a better control mechanism than a roller or paint gun. During painting, straight and long movements should be made on top of each other.

- The best way to get a strong painted surface in the end is to apply several thin coats of paint. After the paint has dried, it should be tested on an inconspicuous edge.

These applications are effective steps for a hard and smooth surface.

Frequently Asked Questions about Film-Faced Plywood

What are the Thicknesses of Film-Faced Plywood?

The thickness of the products also differs depending on the tree species and quality. But as with filmless plywood, the dimensions are similar to those of film-faced plywood. There are filmless plywood thicknesses such as 3mm, 4mm, 6mm, 8mm, 9mm, 12mm, 15mm, 18mm, 21mm, 24mm, 27mm, 30mm, 35mm, 40mm, 50mm. In general, film-faced plywood products have weights of 600-700 kg/m3.

Prices for Film-Faced Plywood 2022

Prices for film-faced plywood vary depending on the wood being processed, its thickness and length.

You can contact Baba Yapı for information about the prices of film-faced plywood.

What are the Tree Types of Film-Faced Plywood?

The same is consumed with trees of Raw plywood species. Film-faced plywood wood species include poplar, beech marine, pine marine, birch marine and exotic. It is usually obtained from trees growing in temperate and cold climates. The only difference from raw plywood types is the use of glue in film-faced plywood. There are varieties with film-faced, such as Russian, Brazilian, Vietnamese, Indonesian, Finnish, Indian, Malaysian, Romanian.

What Should be Considered when Using Film-Faced Plywood?

The same is consumed with trees of raw plywood species. Film-faced plywood wood species include poplar, beech marine, pine marine, birch marine and exotic. It is usually obtained from trees growing in temperate and cold climates. The only difference from raw plywood types is the use of glue in film-faced plywood.

There are varieties with film-faced, such as Russian, Brazilian, Vietnamese, Indonesian, Finnish, Indian, Malaysian, Romanian.

How to Buy Film-Faced Plywood?

It is possible to place an order either online or by visiting individual stores. It is of great importance that people know the information well in online orders. Because there may be some mistakes in the Internet environment. For this reason, customers tend to go to the stores and place an order by meeting with people who know better. You can contact Baba Yapı to order film-faced plywood.

Does Film-Faced Plywood Mold or Rot?

As with any material, film-faced plywood varies in service life depending on the area used and the person using it. Materials that absorb water in humid places generally get moldy first and can go as far as rot if care is not taken. However, since many materials such as edge paint, mold oil and corner apparatus are used in film-faced plywood, humidification is rare. Therefore, molding or rotting is less common..

What Are the Differences Between Film-Faced Plywood and Filmless Plywood?

There are no significant differences between film-faced plywood and filmless plywood. Contrary to what is widely known, the difference between them is not durability, but only affecting the concrete surface. Film-faced plywood is used on surfaces that cannot be plastered. It is recommended to use filmless plywood on the surfaces to be plastered. Raw plywood is mostly used in areas such as furniture, packaging, printing.

It provides the possibility of plastering raw plywood. Film-faced plywood is mostly used in the construction industry. Plywood replaces traditional wooden moldings. Film-faced plywood is used for creating surfaces that will not be plastered, while filmless plywood is used for non-glossy places of surfaces that will be plastered.

What are the Glue Types of Film-Faced Plywood?

The glue used in this type of plywood is called WBS glue. This glue makes a material resistant to boiling water. It is often used in the manufacture of plywood. This glue does not represent any brand. Thanks to this glue, the plywood becomes both water resistant and their service life is extended. There are two types of WBT glue. These are Phenol WBP Glue and Melamine WBP Glue. Phenol glue has a durability of up to 50-72 hours, while Melamine glue has a durability of up to 5-20 hours.

What Should Be Considered When Buying Film-Faced Plywood?

When buying Film-Faced Plywood, attention should be paid to the type, length, thickness of the product, the structure of the film, and the protection devices on the edges, respectively. The thickness of the product to be taken should be determined according to the need. The quality of each material will vary, as well as when choosing plywood, attention should be paid to the quality of the material to be taken. One of the most important factors is to pay attention to the type of glue used. It should not be overlooked whether there is water-resistant WBS glue or not.