Why Special Plywoods?

Plywood is the condition of sticking the sheets peeled from the trunk of various trees such as exotic, pine, beech, poplar, and birch with the help of special machines, with the help of adhesive, with the fibers perpendicular to each other. Its dimensions vary in thickness and size. Thickness may vary between 2.7 - 50 mm.

What are the Uses of Special Plywood?

Plywood can be used in all sectors, especially furniture. It provides great benefits in the field of construction due to its resistance to external conditions. It also has great advantages in terms of price and time.

Main places of use;

In construction works

- In mold works

- On scaffolding platforms

- In interior partitions and roofing works

- In the floor and parquet industry

Furniture works

- Door

- Shelf

- In the construction of wooden chairs and tables

- Office furniture

- In the construction of armchairs,

- And in the manufacture of all kinds of furniture

In transport and shipbuilding

- On the floor and side walls of truck trailers

- On the floors of containers

- On the floor and side walls of wagons

- In animal transport vehicles

- On the ground and sidewalks of vehicles such as buses, trucks. Also in the manufacture of many spare parts.

- For the manufacture of ships, boats and many offshore vehicles.

Packaging

- The material has high resistance to moisture and chemical material.

- It is cheaper than other materials.

- It is more durable and lightweight.

- It is safe and hygienic.

- It is a reusable and environmentally friendly material.

- It can be used in all kinds of packaging.

Other places of use:

- Toys

- In game halls

- In musical instruments

- In the construction of music columns

- Traffic signs, billboards and urban furniture

- Garden huts

- On basketball hoops and skating platforms

- Wall climbing boards

- Grandstand, stage and show construction

- In the production of kitchen and bathroom cabinets, countertops.

- Textile machine tables and cutting machines, making machine models

And it continues to be used in many more areas.

What is Poplar Plywood?

Poplar plywood is obtained by gluing at least three layers or more layers on top of each other perpendicular to each other by pressing the fibers of thin peeling boards obtained by peeling logs with certain properties with the help of special machines.

Due to its soft structure, it is more preferred in indoor applications. Poplar has a low resistance to surface abrasion due to its soft structure.

What Is Flexible Plywood And Where Is It Used?

Usage areas of plywood are quite wide. It is used in many places, from the construction industry to furniture and decoration. The names of plywood products are taken according to the tree in which they were used. Flexible plywood is a variety obtained from non-hardwoods. Its scope of use is quite widespread. It is especially preferred in the manufacture of oval or non-flat forms. During preference, it is preferred according to the direction to be given in the field of use as COLLATERAL or VERTICAL, which determines the fiber direction of the material. Due to the low coefficient of stretching of other plywood, it allows intensive use in areas that cannot be solved with standard plywood.

What are the Uses of Melamine Coated Plywood?

The uses of melamine-coated plywood are also wider than they are known. It would not be wrong to say that it is used in almost every field. It is possible to use melamine-coated plywood in kitchen cabinet coverings, body and covers of cabinets, bedroom furniture, chests, bathroom cabinets, and all other parts of the house. The use of melamine-coated plywood is available not only at home, but also in many places.

The degreased structure of wooden surfaces against contamination and stain resistance turns into an advantage as a result of using products with melamine coating.

What Is Laminate-Coated Plywood And Where Is It Used?

It is preferred more intensively in areas where different surface decors are desired. Laminate materials are preferred in interior furniture manufacturing due to their hard surface structure and erasable surface properties.

Laminate-coated plywood is used more in;

- Interior furniture manufacturing

- Manufacturing of children's rooms and children's playgrounds

- Production of school and office furniture

- The manufacture of park garden furniture and equipment

- Laboratory furniture manufacturing and machine tool manufacturing

- Caravan and tinyhouse manufacturing

- Manufacturing of kitchen and bathroom furniture

It has more intensive use in many areas.

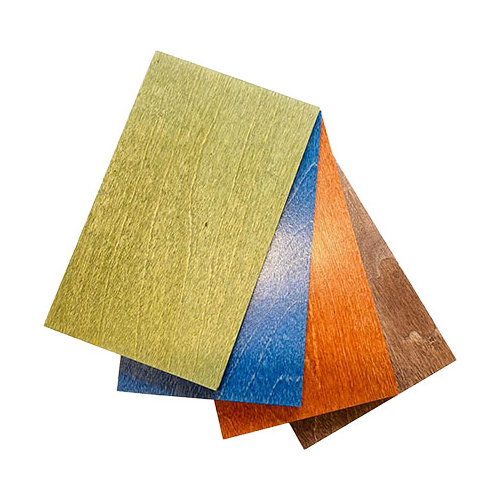

What is Painted Plywood?

Plywood with a structure suitable for painting surfaces is preferred for indoor and outdoor applications on one side or both sides. Having a calibrated structure minimizes fiber in water-based paint processes.

It is recommended to consult with experts for the types of paints to be preferred.

Surfaces can be treated with any kind of paint. The paint process provides protection against stains and many factors that may occur on the surface. Different color and varnish preferences can be applied.