Types of Plywood Used in Trailer, Semi-Trailer and Vehicle Body Production

Plywood is wood product used in many fields. Plywood, which is of great importance in the manufacture of trailers and semitrailers, has different properties according to its usage areas. It is prepared by combining plywood tree layers with special glues under high pressure. It is preferred because of its high abrasion resistance, resistance to external forces, and water resistance in trailer and semi-trailer manufacturing, side wall and floor coverings, and container floors.

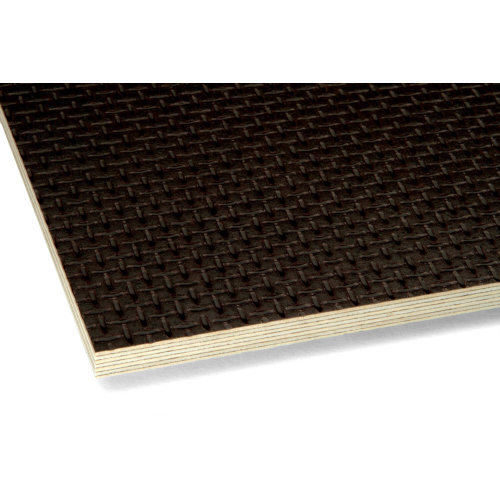

Usage Areas of Wiremesh & Tex (Serrated Surface) Plywood

Birch plywood products which can be used in the manufacture of trailers serrated peeling of the coating drying process following the special, high-pressure presses plywood glued with special glue and phenolic resin obtained by hot pressing surface and edge after calibration is obtained by coating the panel with high abrasion resistance. The upper surface has a serrated (W) and the lower surface has a glossy slippery (F) surface. The coated phenolic resin impregnated kraft papers provide the highest resistance against many chemicals and external factors that may cause abrasion. Its features include anti-slip, high wear resistance, and water and weather resistance. The usage areas of serrated plywood products are as follows:

- Trailer base,

- Caravan, special vehicle floors

- Platform, stage, outdoor exhibition areas floor covering,

- On other floors where high shear strength is required,

It is the most suitable plywood product for trailer and trailer floors and it both prevents slipping and is more resistant to external factors.

Why is Filmless Plywood Preferred in Trailer and Vehicle Body Industry?

Raw plywood products are also among the plywood types preferred in trailer and vehicle body production. Raw plywood products are preferred as floor and side wall covering products in trucks. If special surface treatments such as epoxy coating will be made on the plywood in usage areas, filmless plywood is preferred. Since the surfaces are solid natural coating, it provides much better adhesion resistance in special coatings to be made on the surface.

What Is Plywood Trailer Baseboard?

Plywood trailer base board is a birch plywood product with 18-21-24-30 mm thickness, one side is serrated (W) and the other side is glossy (F) film-faced birch plywood products. It is specially produced for semi-trailers and trailers. The plywood trailer base board is highly resistant to all weather conditions.

What are the Features of Plywood Trailer Floorboard?

Plywood Products used in the trailer, semi-trailer, and vehicle body floor covering processes are preferred because of their superior properties. Product features include:

- It is produced from birch wood peeling veneers, thanks to its special glue structure, it does not open in layers.

- It is generally 1250x2500 mm in size, but it can be produced in many special sizes.

- In general, its thickness is 18-21-24-30 mm, besides, it can be manufactured in many special thicknesses.

- Both sides are coated with a special film made of Kraft paper impregnated with high-strength

- Phenolic resin.

- It has a very high resistance to moisture and water, and has marine (water-contrast) properties.

- It is resistant to all extreme weather conditions.

- They have high carrying capacity.

- The serrated structure of the surfaces allows the loads to remain stable while in motion.

The characteristics of plywood floor covering products indicate that it can be easily used in all areas of use.