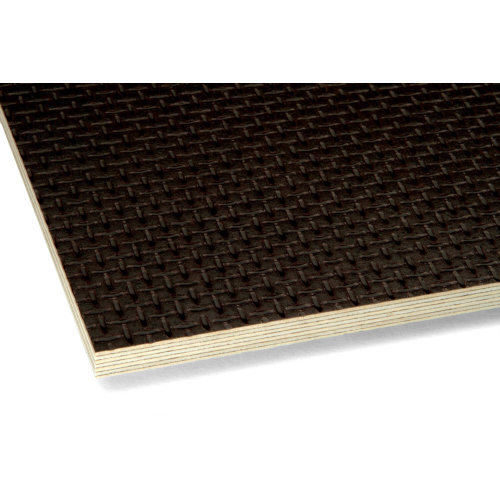

What is Hexa - Tex Wiremesh Plywood?

Wiremesh serrated plywood products have a hexagonal surface structure similar to a bee honeycomb. Raw plywood is obtained by coating the surface of birch products with special phenolic films. Plywood manufacturers can produce plywood in different surface shapes according to their usage areas by using different pattern options. The most preferred pattern is the Hexa Honeycomb pattern plywood surface. The phenolic resin-impregnated special papers used have high abrasion resistance but have high resistance to external factors and chemicals.

Durability of Birch

Since birch is a cold climate tree, it shows better resistance against external factors and weather conditions with its properties. It is covered with honeycomb-patterned phenolic films for non-slip, resistance to chemicals, protection against water, and other external factors in usage areas.

Where is Wiremesh Serrated Plywood Used?

Hexa - Plywood (serrated plywood) products are used in floor, ceiling and sidewall coating processes in many areas. By selecting products according to their usage areas, the desired decoration operations can be easily performed. The following are the uses of wiremesh serrated plywood products.

- Trailer and semi-trailer bases and sidewalls,

- Music box manufacturing,

- Cold storage,

- Stage and platform floors,

- Turbine floors and walkways,

- Logistic warehouse floors and shelves,

They are coating materials with high friction and slip strength due to the special pattern found on honeycomb pattern plywood products. Plywood can be supplied in different thicknesses according to the areas of use, choosing plywood types with honeycomb textured surface while choosing will provide products with both decoration and durability. In the areas of use, it will find the best solutions to slip problems and provide durability with its strength feature.

What are the Advantages of Wiremesh Serrated Plywood?

The surface of hexa plywood products produced using birch layers is covered with phenolic film with honeycomb pattern. Because it is coated with honeycomb patterned film, it creates high resistance to abrasion and sliding. In honeycomb plywood products, the area to be used on the upper side is patterned (HEXA), while the other surface is more flat and smooth (F). Wiremesh serrated plywood products provide various advantages in all areas of use.

- Provides decorative appearance,

- It has high resistance to high abrasion,

- Resistant to all weather conditions,

- Resistant to water and moisture,

- Resistant to chemicals and easy to clean,

- It is a hygienic and environmentally friendly product,

- It is processable,

- It has a high carrying capacity.

These features allow you to create the desired strength more conveniently in all areas of use, such as trailers, trailers, warehouses, floors. Due to the fact that it has a lot of advantages over its areas of use, it is considered the most suitable plywood product, especially for floor covering areas. Since it can be used in many indoor and outdoor areas, the demand rate is quite high.

How are Hexa Plywood Dimensions Determined?

Hexa plywood products are custom-made according to their usage areas. It has different dimensions to be suitable for its intended use. Thickness measurements are usually, 6,5-9-12-15-18 mm. As for the dimensions, they are generally designed as 1250 x 2500 mm. Hexa plywood is used to eliminate the problem of slipping in many areas of use such as stage floors, truck trailers, commercial vehicle bases, industrial floors. Dimensions are determined according to the area to be used and orders are given accordingly.